In today’s world, industries face increasing pressure to adopt sustainable practices, and one of the most significant challenges is ensuring access to clean and safe water. Reverse Osmosis (RO) has become a cornerstone of water purification in various industries due to its reliability and efficiency. However, selecting the right RO system for industrial applications can be a daunting task. The choice depends on factors such as water quality, system size, capacity, and cost-effectiveness. This article will guide you through the essential considerations for choosing the best Reverse Osmosis system for your industrial water treatment needs.

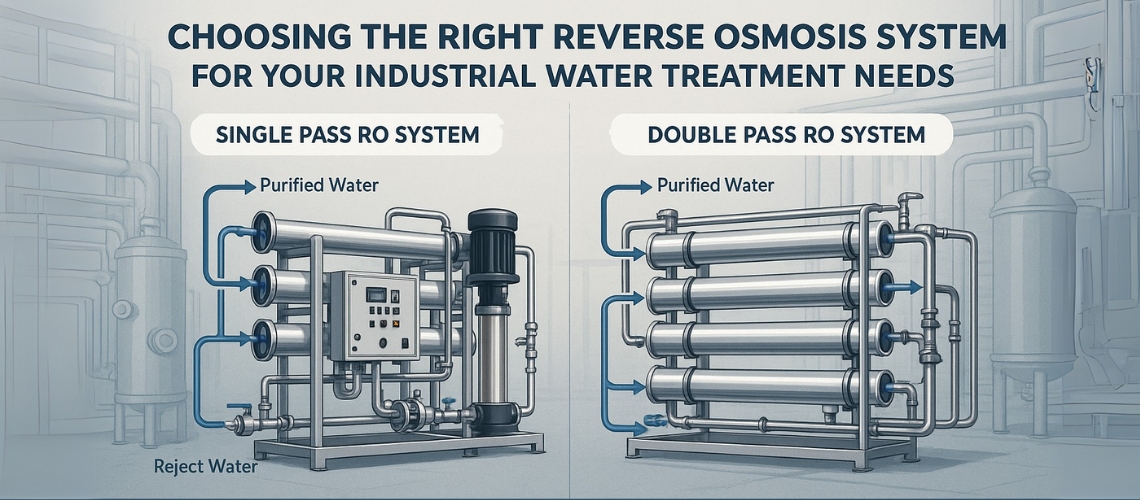

Before diving into the specifics of choosing the right RO system, it’s important to understand the two primary types of Reverse Osmosis systems used in industrial applications.

Single Pass RO System

A Single Pass RO system is ideal for treating water with low to moderate contamination levels. The water undergoes pre-treatment, passes through the RO membrane, and is released as purified water. This system is often used for applications like drinking water production and light industrial processes where water quality requirements are not as stringent.

Double Pass RO System

A Double Pass RO system offers higher purity and is typically used in industries where ultra-pure water is essential, such as pharmaceuticals, electronics, and the semiconductor industry. In a double-pass system, water is treated through two stages of RO membranes, ensuring even higher purity. The output water conductivity can be as low as 1-10 μs/cm, making it ideal for high-purity industrial applications.

When choosing an RO system for industrial use, it’s important to consider several factors to ensure the system meets your needs effectively and efficiently.

Water Quality and Contaminant Levels

The first step in selecting an RO system is assessing the quality of your feed water. Factors like hardness, Total Dissolved Solids (TDS), chemical composition, and contamination levels will determine the type of pre-treatment and RO system required.

System Capacity

Another important factor is the capacity of the RO system, measured in liters per hour (LPH) or gallons per day (GPD). The right system depends on your water usage and demand.

Energy Efficiency and Operational Costs

Energy consumption is a significant factor in the operational cost of RO systems. As large-scale RO systems can be energy-intensive, opting for energy-efficient models can help reduce long-term operational costs.

Many modern RO systems come equipped with energy recovery devices that recycle pressure from the brine stream, reducing overall energy use and making these systems more eco-friendly and cost-effective.

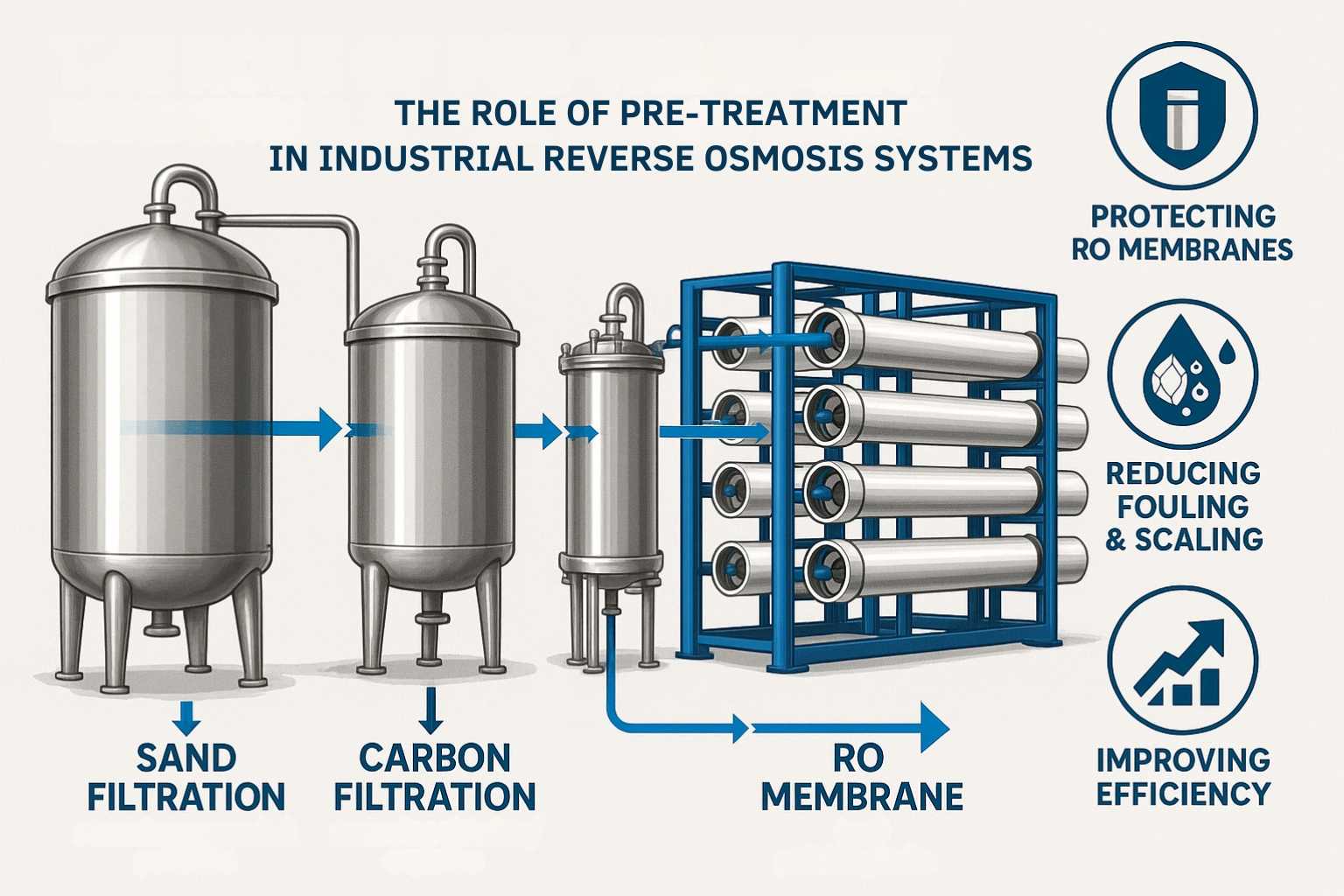

Pre-treatment is crucial to the longevity and effectiveness of any RO system. In industrial applications, poor water quality can lead to rapid fouling and scaling of the RO membrane, which reduces performance and shortens its lifespan. Pre-treatment processes involve filtering out large particles, chlorine, and minerals that could damage the system.

Types of Pre-Treatment:

Proper pre-treatment not only protects the RO membrane but also optimizes its performance and extends its service life, making it a critical component in the selection of the right RO system.

Once you have chosen the right RO system, it’s important to optimize its performance to ensure high efficiency and minimal downtime.

Membrane Maintenance

RO membranes require regular maintenance to prevent fouling and scaling. Cleaning protocols using chemicals like citric acid or sodium hydroxide can help remove mineral build-up, bacteria, and organic fouling. Periodic membrane replacement may also be necessary depending on the system’s operational environment.

Pressure Optimization

Pressure is a critical factor in the RO process. The higher the pressure, the more efficient the filtration process. However, excessive pressure can lead to membrane damage. Therefore, maintaining the optimal pressure levels is key to maximizing RO system performance.

Monitoring and Automation

Many modern RO systems come equipped with automated monitoring systems that track key parameters such as flow rates, pressure, and water quality. Automated systems can help identify inefficiencies, saving time and resources while ensuring the RO system continues to operate at peak performance.

In industries like food and beverage, pharmaceuticals, and electronics, the quality of water used in production processes is critical. RO systems are vital in ensuring that the water meets stringent purity standards, which directly impacts the quality and consistency of end products.

Food & Beverage Industry

In the food and beverage sector, the purity of water is essential for maintaining product quality. RO systems ensure that water used in beverages, dairy, or processed foods is free from contaminants, ensuring taste consistency and safety.

Pharmaceutical Industry

Pharmaceutical manufacturing requires ultra-pure water to meet regulatory standards. Double Pass RO systems are typically used in these industries to ensure that water quality is maintained at the highest level.

Electronics and Semiconductor Industry

In electronics and semiconductor manufacturing, water quality is crucial for the proper functioning of delicate equipment. RO water is used to prevent contamination in the production process, ensuring the reliability and precision of the final product.

Reverse Osmosis systems are not just about ensuring water purity; they also offer significant environmental and economic benefits.

Eco-Friendly Water Treatment

RO systems can help industries reduce their water consumption by recycling and reusing water. Wastewater treatment and reuse using RO technology contribute to water conservation, reducing the strain on local water resources.

Cost-Effectiveness

While RO systems may require an initial investment, they are highly cost-effective in the long run. By using energy-efficient technologies, such as energy recovery devices, industries can minimize operational costs while maximizing water treatment efficiency.

While RO systems offer numerous benefits, there are several challenges that industries may encounter during their implementation and operation.

Membrane Fouling

Membrane fouling occurs when contaminants build up on the surface of the RO membrane, reducing its performance. Regular cleaning and the use of pre-treatment processes can help mitigate fouling and maintain system efficiency.

Energy Consumption

RO systems can be energy-intensive, especially for large-scale operations. However, with the use of energy recovery devices, energy consumption can be significantly reduced, making the system more efficient and environmentally friendly.

Wastewater Disposal

The brine or concentrate produced by the RO system must be properly disposed of, especially in large-scale operations. Environmental regulations often dictate how this concentrate should be handled, and industries must ensure proper disposal methods are in place to avoid environmental damage.

Choosing the right supplier is as crucial as selecting the right system. A reputable supplier will provide you with high-quality systems, expert advice, and excellent after-sales support.

Reputation and Experience

Look for suppliers with a solid reputation in the industry. Suppliers with years of experience and proven success in industrial water treatment are more likely to provide reliable and effective solutions.

Support and Warranty

Ensure the supplier offers comprehensive after-sales support, including warranty services and regular maintenance. This will help protect your investment and ensure the system operates optimally over time.

Choosing the right RO system for your industrial water treatment needs is a crucial decision that requires careful consideration of factors like water quality, system capacity, energy efficiency, and cost-effectiveness. By understanding the different types of RO systems, the importance of pre-treatment, and how to optimize performance, you can ensure that your RO system meets your operational needs and delivers the best return on investment.

Partner with experienced suppliers and ensure that your RO system is designed to meet your unique water treatment requirements. Whether it’s for drinking water, industrial processes, or wastewater treatment, choosing the right system will ensure your industry operates efficiently and sustainably.

At Kunsheng Water Treatment Co., Ltd., we offer customized RO solutions tailored to meet the unique needs of your industry. Our systems are designed for efficiency, reliability, and long-term performance, ensuring that you receive the best water treatment solution for your operations.

Contact Kunsheng today to explore our range of RO systems and learn how we can help you achieve cleaner, safer water for your industrial processes.

Olivia : +86 15168506513

Lydia : +86 15253672282