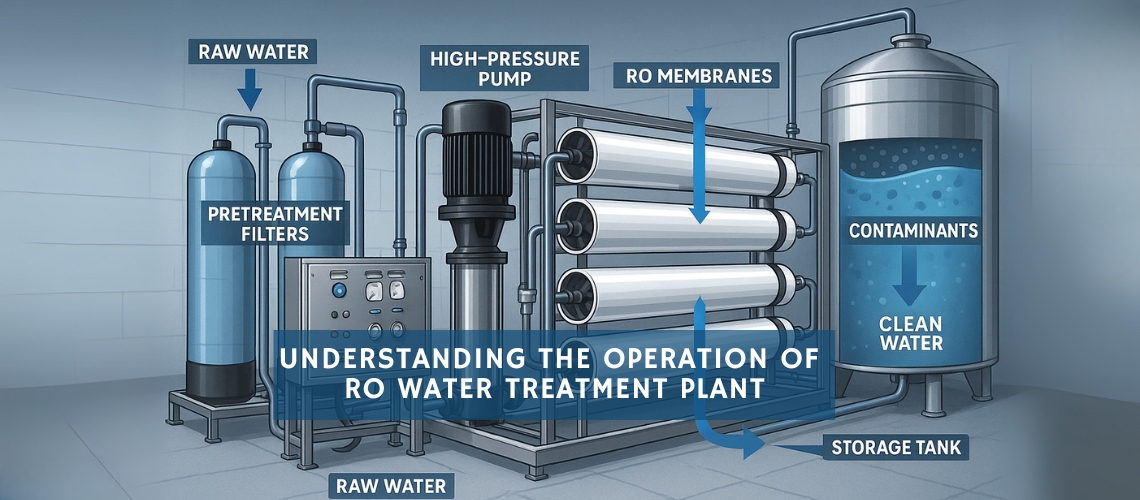

The process of Reverse Osmosis can be broken down into several key steps, each contributing to the purification of water.

- Pre-Treatment: The First Line of Defense

Before water enters the RO system, it undergoes pre-treatment to remove larger particles and contaminants that could damage the RO membrane. This stage is essential for the longevity and efficiency of the system and includes:

- Sediment Filtration: Removes large particles like sand, dirt, and debris.

- Activated Carbon Filtration: Removes chlorine, chloramine, and organic compounds that could affect the taste or damage the RO membrane.

- Water Softening: In areas with hard water, a water softener is used to remove minerals such as calcium and magnesium, which can cause scaling on the RO membrane.

- High-Pressure Pump

After pre-treatment, the water is pumped into the RO system by a high-pressure pump. The pump forces the water through the semi-permeable membrane, overcoming natural osmotic pressure. The pressure applied must exceed the osmotic pressure of the water to effectively separate clean water from contaminants.

- The RO Membrane: The Core of the Process

At the heart of the RO system is the semi-permeable membrane, which plays a crucial role in filtering out contaminants. The membrane has microscopic pores (typically 0.0001 microns), allowing only water molecules to pass through. Contaminants such as salts, heavy metals, bacteria, and viruses are left behind and eventually flushed away as concentrate or brine.

- Salt Rejection Rate: RO systems can achieve up to 99% removal of dissolved salts and contaminants, ensuring that the permeate (clean water) meets safety and quality standards.

- Permeate and Concentrate: The permeate is the purified water that passes through the membrane, while the concentrate contains the rejected contaminants and is typically discarded or reprocessed in larger systems.

- Post-Treatment: Polishing the Final Product

Once water passes through the RO membrane, it may undergo additional post-treatment processes to enhance its quality:

- UV Sterilization: Ensures the water is free of microbial contaminants. UV light effectively inactivates bacteria, viruses, and other pathogens.

- Ozonation: Ozone is used to oxidize and disinfect the water, further ensuring its safety for consumption.

- Re-mineralization: For mineral water production, minerals like calcium and magnesium are added back to the water to enhance taste and provide health benefits.